Various field experiences and systematic construction

Precision machining and manufacturing according

to electromagnetic wave characteristics

Our Excellent Technology

SEMITEC Engineering was established in 1995 by composing technology and professional manpower, starting with EMC Chamber Solution design, consulting, and technology development in 1990. Immediately after that, it has been supplying a number of EMC shielding facilities by localizing and developing Modular Pan Type Shielding Panel and Shielding Door, which had been dependent on imports through its own technology development.

In addition, through continuous technology development, improvement, and verification process of core parts and countermeasure parts of various chamber configurations, we are producing and supplying certified products that meet the highest quality and requirements suitable for EMC standards according to today's changes in electromagnetic wave characteristics and test environment.

To provide EMC test equipment that meet the special conditions required by customers, such as RF Shielded Enclosure, Anechoic Chamber, EMP (Electromagnetic Pulse) protection cabinet and protection facilities, we expanded production facilities and established an affiliated Research Institute, and our experts from fields related to electronics, electricity and machinery are providing EMC Chamber Solution for all support with development of new technologies through ISO certification and utilizing its own technology and patents, including the following

- Optimal in-house design and simulation through CAD/CAM

- Precision machining and manufacturing according to electromagnetic wave characteristics

- Systematic construction based on various field experiences

- Prompt and thorough follow-up management, etc.

We provide EMC Chamber Solution for all support.

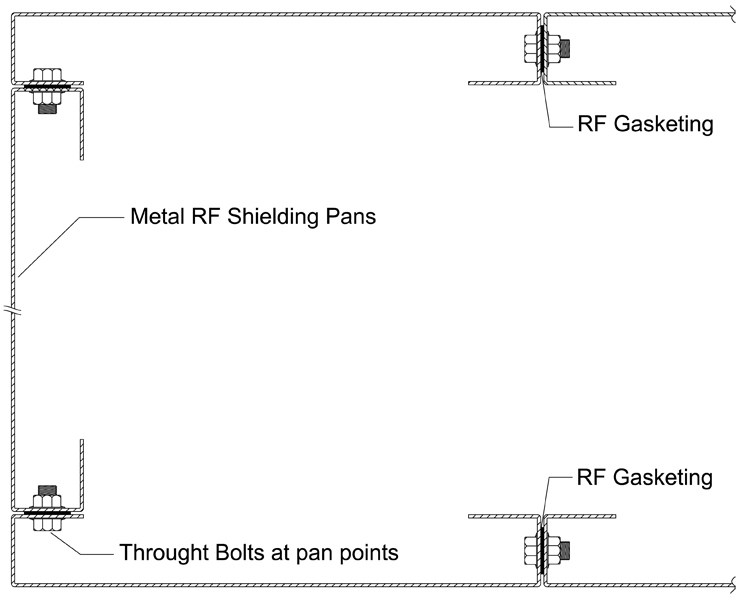

Pan Modular System

- Shielding Panel is manufactured by bending a 2mm thick high-temperature galvanized steel sheet into a ‘ㄷ’-shape according to the standard.

- Each panel is connected and attached using bolts at intervals of 10cm.

- High-conductivity RF gasket specially designed to block noise inflow and outflow for assembly when panel connection is used to improve shielding performance.

- Chamber and Shielding Room of the desired size can be manufactured.

- Economical because it is easy to dismantle and relocate

- Fully enclosed freestanding installation

- Very strong against environmental influences such as temperature, humidity and corrosion

- High shielding performance certification for both low and high frequencies

- Clean appearance and excellent durability

-

Wall and Ceiling Detail

Modular Pan Panel Type

Wall and Ceiling Detail

Modular Pan Panel Type

RF Shielding Door

- The frame and leaf of the Shielding Door are made of 2mm thick galvanized steel sheet.

- Dual shielding effect with dual knife structure of finger contact surface

- Pneumatic, electric motor method

- Exterior finish: Powder coating

- Design and manufacture of Auto Ramp and Slope system with no internal and external height difference according to the required load for easy sample loading

- Manufacture of shielding doors suitable for RF, EMC, EMP standards of MIL-STD-285, IEEE 299-1997, and MIL-STD-188-125

- Size/Type can be manufactured according to customer requirements and specifications.

- Shielding effect 100dB up to 40GHz can be produced.

- Safety device (emergency stop sensor, internal/external manual opening and closing device in case of emergency, safety manual handle installed)

- Guaranteed safety, durability and shielding performance